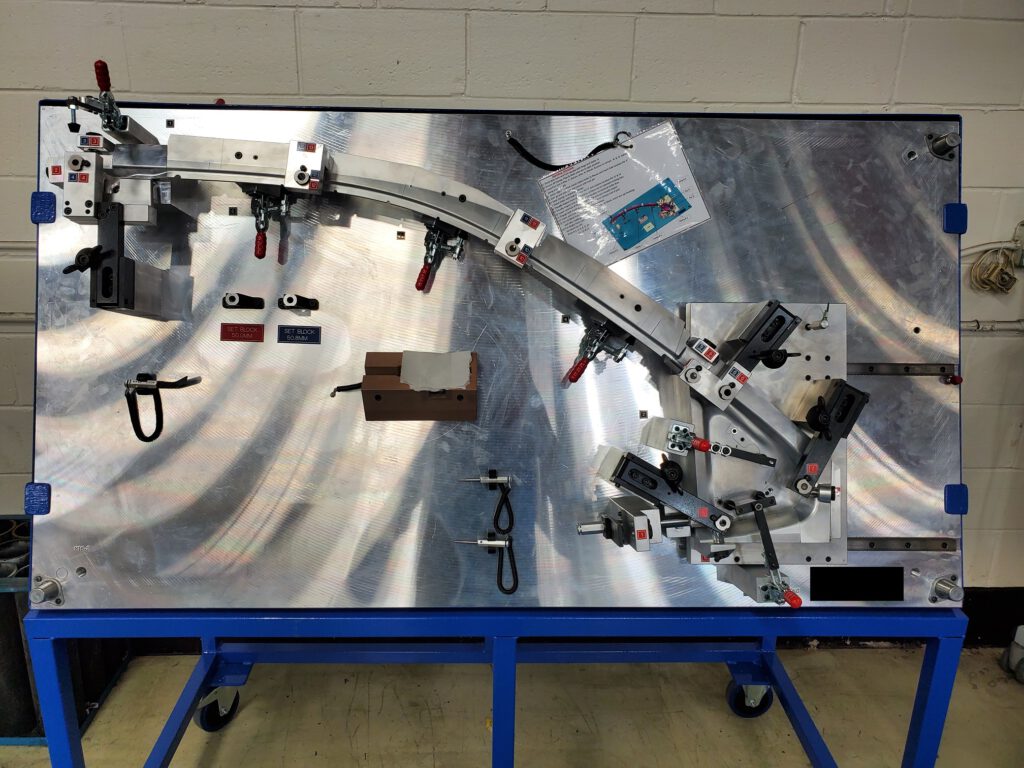

Checking fixtures are designed for accuracy, repeatability and reliability with a strong focus on operator ergonomics.

The checking fixture is a convenient tool used by industrial production companies to control the dimensions of auto parts (such as trim edge,surface profile , hole size, flatness, etc.), it is suitable for mass production of parts detection.

Different types of checking fixtures

· CMM fixtures

It is composed of fixations and centring elements, which enable to spot the part in the specific space as well as to control it using the CMM machine.

· Cubings

It represents the environment of the assembly or part to be controlled and exact simulation of components, which surrounding the parts. This fixture type includes both fixations and centring elements. It also has controls by the measuring instruments and Go/No Go.

· Check fixtures with digital measuring instrument controls and Go/ No Go

This type of fixture comprises of fixations and centring elements of the parts and has manual controls by measuring device or Go/ No Go to offer accurate digital value than nominal value. It includes digital probe, dial indicator, incomplete, and so on.

· Automated checking fixtures

Like other fixture types, it also has centring elements and fixations but comes with the automated controls in order to obtain the shorter cycle time to enable and control 100percent of the production.