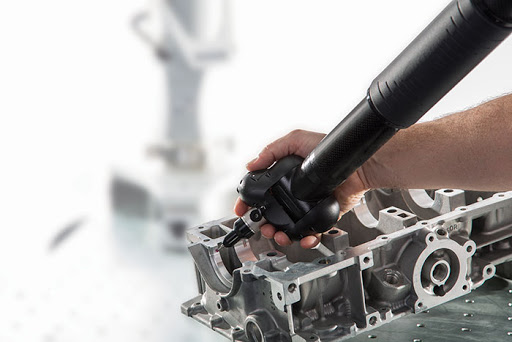

The ROMER Absolute Arm is the first measuring arm which does not require referencing before measurement. When the arm is turned on, it’s ready to go.

Quality control, inspection, on-machine verification, reverse engineering, virtual assembly or 3D modelling. Wherever these needs arise, you will find the ROMER Absolute Arm. Much more than just a metrology tool, its value lies in its versatility. Portability, stability, light weight and high-performance laser scanners make the ROMER Absolute Arm an all-purpose 3D measurement, analysis and digitising tool that can be used by anyone, anywhere and with minimum training.

Unlike many metrology devices, the ROMER Absolute Arm does not require warm-up time or initialization, thanks to a stable carbon fiber structure and industry leading Absolute encoders. Simply take the measuring arm to the part, switch it on and start measuring.

Increasing productivity across all industries.

| Typical Industries: | Typical Measuring Applications: |

| Automotive | Sheet Metal Parts |

| Aerospace | Dies & Molds/Tooling |

| Power Generation / Wind Energy | Machined Parts |

| Forming Industry | Jigs & Fixture setup and alignment |

| Casting Industry | Tubes & Tube Assembly |

| Fabricated metal products | CAD-to-Part comparison |

| Machinery Manufacturing | Alignment |

| Sports Equipment | Reverse Engineering |

| Piping & Tubing | Virtual Assembly |

| Agriculture & Heavy Equipment | Body in White |

| Ship and Boat building | On-machine tool inspection |

| Railway | Composites inspection |

| Archaeological and Historic Preservation | Die-Casting and Patterns |

https://www.hexagonmi.com/products/portable-measuring-arms/romer-absolute-arm